Crafting the Future: The Modern Mason and the Evolution of Manufactured Stone Veneer

The world of stone masonry is where the resilience of ancient quarries resonates with the pioneering spirit of the present. Let’s explore the evolution and profound impact of manufactured stone veneer (MSV) on the craft.

Table of Contents

Table of Contents

Introduction

The world of stone masonry is where the resilience of ancient quarries resonates with the pioneering spirit of the present. Let’s explore the evolution and profound impact of manufactured stone veneer (MSV) on the craft.

Stone masonry, the creation of enduring structures and sculptures using stone, stands as one of humanity’s most ancient and resilient trades. From its inception, where stone, mud, and straw crafted the simplest of homes, to the grandeur of lasting monuments, this craft has been a testament to human ingenuity and perseverance.

Historical Evolution of Stone Masonry

Stone masonry traces its origins back to ancient civilizations, where stone was used with mud and straw to create simple homes. The rudimentary yet revolutionary use of stone laid the foundations for future marvels. Despite its humble beginnings, it evolved into a means to build long-lasting monuments to some of the greatest civilizations.

From Sacred Burial Sites to Gothic Cathedrals

The Middle Ages heralded a new era for masons, turning them into specialized craftsmen. The skilled craftsmen behind Gothic cathedrals used basic tools such as compasses, set squares, and marked staffs or ropes for precision in their intricate stonework. These tools and techniques, including strategic mortar use, are an innovation that contributed to the stability and aesthetic of the cathedrals.

The Renaissance and the Industrial Revolution

The mastery over stone was further refined during the Renaissance and the Industrial Revolution. With the Renaissance came a revival of classical architecture and the rise of humanist philosophy, which drove masons to push the boundaries of design and construction to erect structures that would withstand the test of time. Italy took center stage during this period with the Laurentian Library, Fountain of Neptune, and Florence Cathedral, which can be admired today.

The Rise of Manufactured Stone Veneer

The narrative of stone veneer weaves through history, from Roman engineering marvels adorned with early forms of veneer to the transformative advent of MSV post-World War II. This innovation marked a pivotal turn in masonry, combining traditional craftsmanship with the advantages of modern technology — reduced weight, ease of installation, and unparalleled aesthetic appeal.

For example, the Roman Coliseum still bears the marks of where anchors once held marble veneers. During the 1800s, stone veneers made of granite, marble, travertine, limestone, and slate were in use. It was the development of stone veneer in the post-World War II era that masonry really hit a turning point.

With the advent of skeletal steel framing, which allowed for the construction of taller buildings, the need to minimize the dead weight of masonry walls arose. This is where stone veneers became the perfect solution. Typically measuring only one and a half inches in thickness, they were a fraction of the weird compared to traditional walls of that era. By the 1980s, they had been reduced to 1/8th inch, reaching a mere 3 cm by the early 2000s.

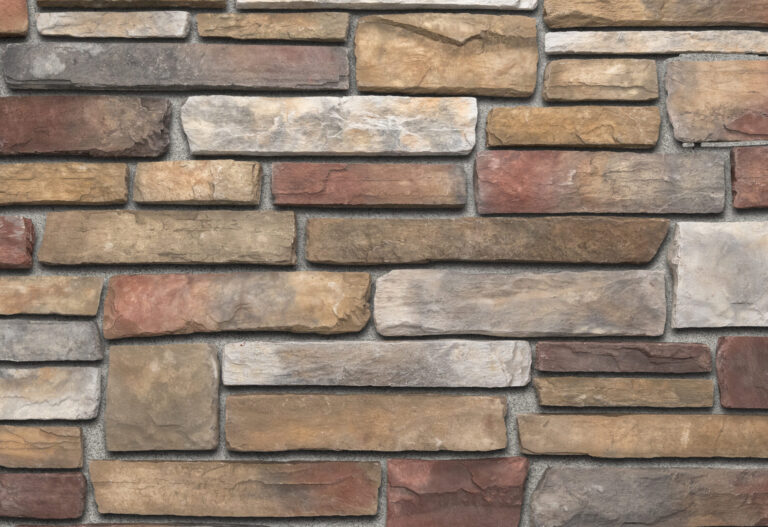

Developed in the early 60’s, manufactured stone veneers (MSV) were initially a concrete-based mixture. It was cast in carefully selected natural stone molds and then hand-colored with iron oxide pigments to capture the finest details from the surface of the original stone. Advantages soon emerged: consistent quality, customizable specifications, reduced weight, and easier installation.

The Renaissance and the Industrial Revolution

Today’s masons are the standard-bearers of both tradition and innovation. They blend time-honored stone-working skills with cutting-edge techniques, particularly in the use of MSV which can also be described as faux stone veneer.

The rise in MSV use has led to several architectural and interior design trends. One such trend is to pair natural stone with MSV to create visually exciting and dynamic aesthetics. This trend is often observed with pools where the stairs may be natural stone, while the retaining walls consist of manufactured veneer siding. The dynamic natural stone and MSV duo allows for a much more seamless end product. The lightweight nature of the faux stone will also enable masons to explore shapes and forms that were previously challenging or expensive to achieve with natural stone. This allows for creative expression and architectural feats once deemed impossible, showcasing the resilience, integrity, and hard work inherent in every Toro Stone product.

Toro Stone believes in building consistent, high-quality veneers and relationships with masons/contractors everywhere. This is why we have made it a point to provide high-quality, accessible materials that are strong enough to stand up to even the most challenging project.

Break the Mold with Toro Stone

Each stone veneer laid is not just a piece of material but a declaration of strength, a commitment to excellence, and a step toward building lasting legacies. This is the story of stone masonry, etching its legacy in every stone veneer laid—including those by Toro Stone. Toro Stone has perfected the art of replicating the textures, colors, and patterns found in natural stone, allowing seamless integration with most architectural styles or interior design concepts. Toro Stone isn’t just about supplying superior stone veneer; it’s about forging partnerships and building communities, one stone at a time.